At this week’s pre-Drupa media conference the company announced the new S11 and S11P (perfecting) B1 sheetfed models.

An ‘11K Module’ ups the production speed from 6,500sph to 11,200sph while a new PrintAI module promises to “enhance print quality even further”.

At the last Drupa in 2016 Landa showed the S10 running at 13,000sph, which had been the high-speed goal from the outset of the project back at Drupa 2012.

Founder Benny Landa explained: “We showed a machine running at 13,000sph. But the difference between a demo and making that machine consistently, reliably, with super quality colour day in day out 24/7… you have to walk before you run.

“We started at 6,500. Now we’re up at 11,200 and in the future we will go even higher,” he stated.

“Each step takes quite a while to stabilise as you push the envelope to the limits of the data rates, the chain speeds etc.”

Landa Digital Printing CEO Gil Oron said: “These are very exciting times for Landa Digital Printing. After an investment of over €1bn we are now experiencing rapid growth with very, very strong ramp-up. And actually we are doubling our business year after year.”

He highlighted the firm’s diverse customer base, with 55 presses now installed or in the process of being installed.

“And we also have many repeat orders – eight customers have purchased a second or third press,” he stated.

“A typical customer of ours is printing hundreds of jobs a day, and millions of products a month. This technology enables them to grow their business… and to make money, and that’s not easy as you all know these days. Our customers are making money with our presses.”

He also pointed to sustainability benefits.

“They are getting rid entirely of all printing plates, and are practically eliminating paper waste.”

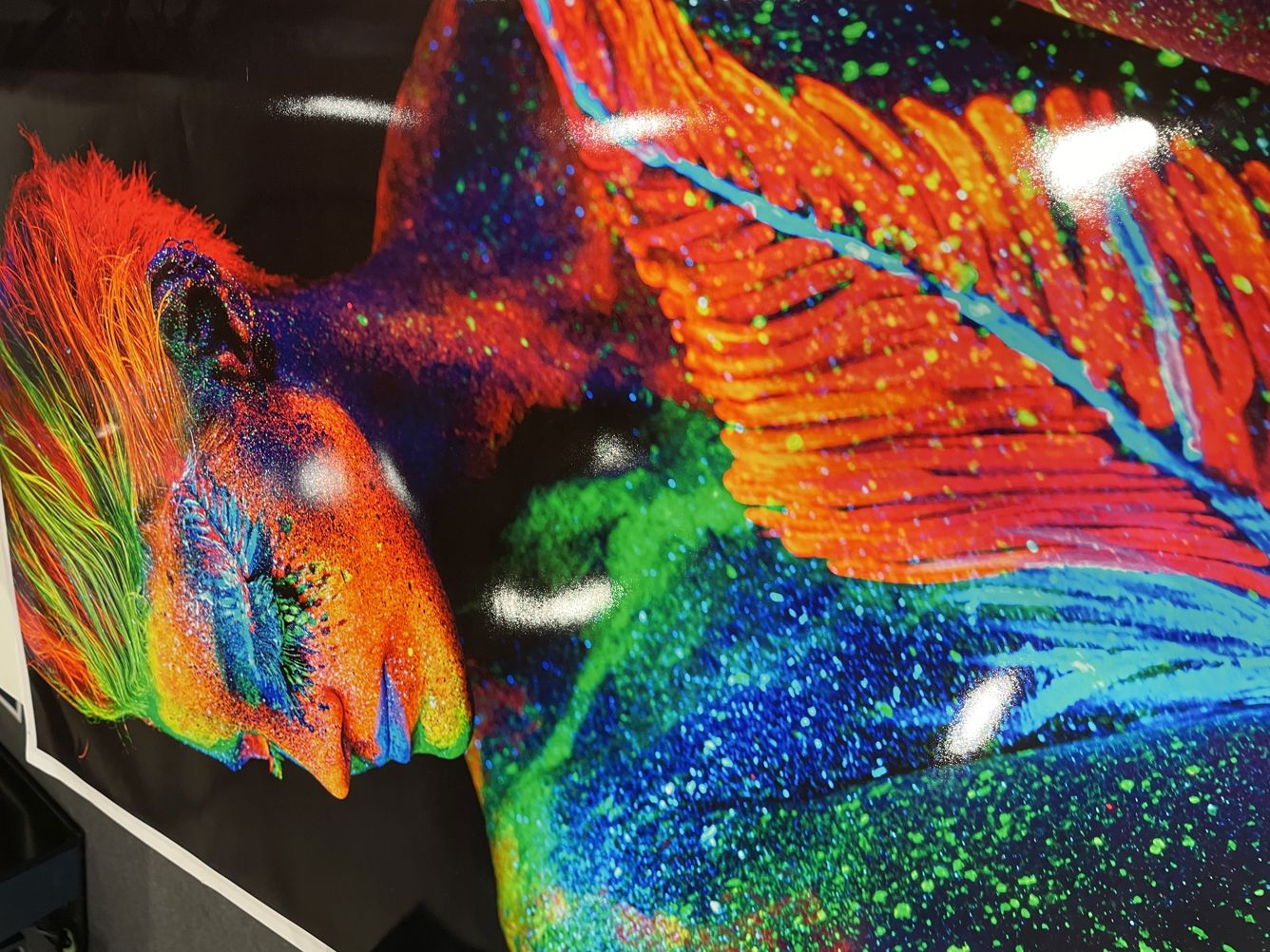

Landa Digital Printing ran a video featuring glowing testimonials from customers, including the UK’s Bluetree Group which has ordered a second S10P press.

Head of operations Chris Down described the first press as “exceptionally reliable now”.

Regarding the new models, CBO Sharon Cohen explained: “There is a difference in the platform, mainly related to the drying system. The new S11 is based on infra-red drying system and some of the latest presses we’ve sold and implemented in the field already came with that ability.”

They will be fully upgraded to the S11 platform.

“The ones from the previous model we’re going to allow for a speed increase, not dead level a different speed, but they’re not going to be left behind.”

The AI module is specifically a software upgrade.

A new manufacturing model involving a “drop shipment approach” enables the business to make more with its existing facilities.

Oron said 100 systems a year could be manufactured with the current setup.

He also said some customers were running their presses 24/7.

“Everyone is starting from a certain point and then getting faster and faster.”

Landa also confirmed that the W11 (previously W10 but has not shipped yet) web-fed press for flexible packaging remains on its product roadmap.