The centre, which will also be offered as an additional location for the Roland DG Academy courses, will focus on new areas of transport design research and developing new ways of designing and prototyping solutions for the automotive, rail, marine and aerospace sectors. It will be used for a range of purposes, including R&D with outside companies to post-graduate education and development.

The NDTC officially opened its doors on 25 May and includes technology that enables augmented, virtual and 'mixed reality' environments as well as 3D printing, large-format flatbed graphics devices and a range of milling machines for the creation of scale models.

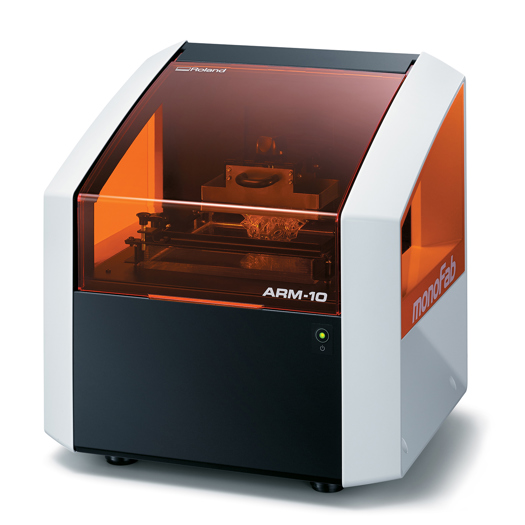

Coventry University already has an established history with Roland DG, with many of its departments having used Roland technology for more than a decade. Now the new NDTC will offer nine devices from the manufacturer, including the monoFab ARM-10 and monoFab SRM-20 3D printing devices, the Modela MDX-50 and MDX-540 milling machines and the CAMM-1 GS-24 desktop cutter, as well as the latest print-and-cut technology from Roland’s TrueVIS range.

“Our partnership with Coventry University is yet another example of how Roland DG is always on the forefront of technology; by working with educational partners and customers to help mould the future of a variety of industries, thanks to the exciting and pioneering work they achieve,” said Roland DG UK’s chief operating officer, Brett Newman.

He added: “With the NDTC facility, our equipment is sure to contribute to the bright future of the transport industry.”

Newman said that using the new facility as an additional site for Roland Academy’s training, open days and demonstrations would enable the company to widen its national scope.

Academy and creative centre manager at Roland DG, Joe Wigzell, added: “Our partnership with Coventry University is a great opportunity for Roland DG. We get a fantastic new space to run our future courses, providing us with a new location for the convenience of our customers. And of course, seeing our machinery used in such a state-of-the-art facility to develop impressive products is a testament to the technology.”