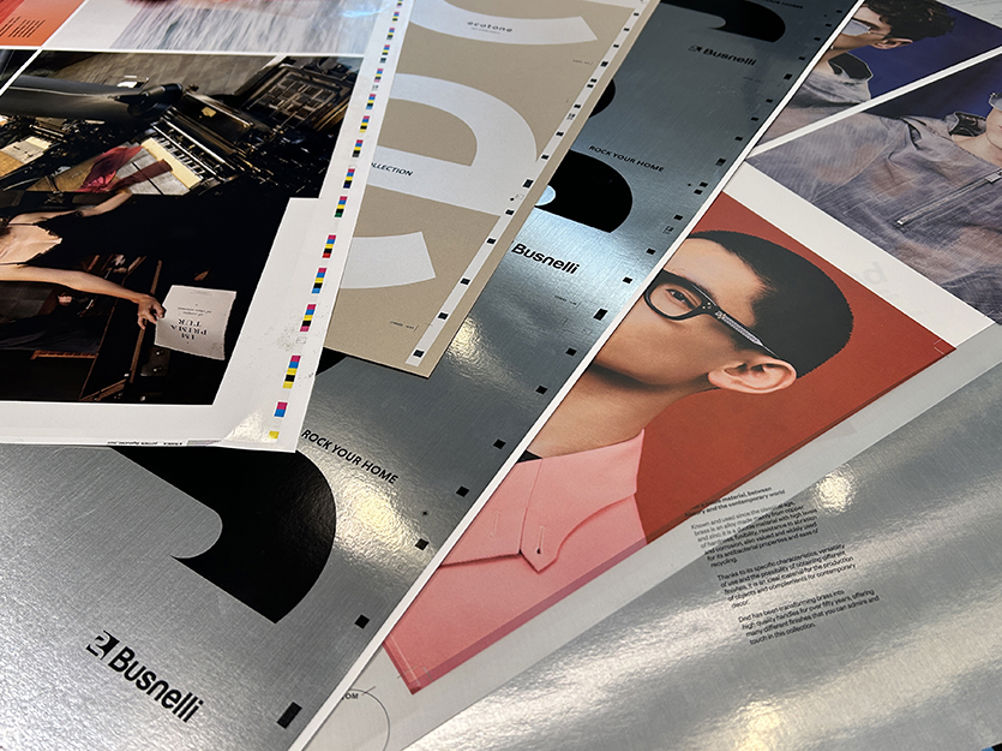

Grafiche Antiga has an enviable client list, producing print and 3D point-of-sale for a range of leading luxury brands under the Louis Vuitton Moët Hennessy umbrella, including Bulgari, Versace, Ralph Lauren and Michael Kors, among many others.

The business was formed in 1968 by the four Antigas brothers: Silvio, Franco, Carlo and Mario, and now employs around 200 people at six sites across northern Italy, with its headquarters and key production facility in Treviso, near Venice.

Grafiche Antiga press manager Amos Michielin has responsibility for all print production output from the Treviso plant.

He said the high expectations of the company’s client base led them on their path to investing in UV LED technology.

“Our customer is demanding... very demanding. As a result, we've always been very careful to keep a close eye on technological evolutions in the world of printing. UV curing was one such innovation that we could not ignore, as it allows us to do things that we simply could not do without it.”

Grafiche Antiga’s high-end work requires the business to constantly push the boundaries of what is possible, using state of-the-art printing techniques and technology to achieve exceptional results.

“With LED, we can now print every type of project for our customers, for example we can print with high gloss varnish, with whites on natural papers, we can print on laminated paper, with one pass, with the white in first unit and four-colour on. We can print on PVC, in one face four-colour and white... black... every type of project, no problem,” explained Michielin.

Having also worked with conventional mercury arc UV systems, Michielin was aware of the sustainability benefits of curing with LED UV.

“Today our customers pay more and more attention to the environmental impact of our work. Curing with LED has a significantly lower impact, both for emissions of ozone and for energy consumption, when compared to a conventional UV system. Greener printing is so important to our customers, and UV LED gives us an advantage by enabling us to offer this,” he said.

“Further to this, because the energy consumption is so much lower than before, it is an investment that pays for itself very quickly, in just a few years.”

Following thorough research into the UV LED curing market and a number of potential UV suppliers, Michelin narrowed his focus down to GEW.

Having been introduced to the UV supplier through Fornietic, GEW’s exclusive distributor for the Italian market, he visited the company’s UK headquarters before committing to a final decision.

“When I went to visit GEW in London, I saw the organisation... not only the lamps and the system, I saw the buildings, I saw the people, the technicians... and I had no doubts,” he said.

Once the buying decision had been made, Michielin put GEW in direct contact with the press manufacturer, Koenig & Bauer. The two parties worked closely to ensure a successful UV system integration with Grafiche Antiga’s new B1 five-colour plus coater Rapida 105-5+C.

“They communicated together immediately and they gave me the result that I wanted. The LED UV system is a perfect integration. It's very versatile, because we have five lamps - three in the delivery and two interdeck, and I can move the interdeck in every print unit within two minutes,” said Michielin.

“Sometimes we have special jobs to do with whites on natural papers. This can lead to us having to use two print units for the white. Being able to quickly move a lamp from first to second position allows us to be even more productive and have less machine downtime. It's very simple. You can control everything with one finger and one touch panel. We don't have any problems, we almost forget we have the UV system in the machine… it is so simple to use, easy and reliable.”

Michielin continues on the topic of production benefits: “With the LED system the sheet is dry immediately, giving sharper images and a more vibrant colour, particularly on uncoated papers. Sheets can go immediately in the finisher and the print quality is always preserved, one hundred percent. The removal of the need for spray powder further reduces any quality issues and creates a cleaner environment.”

Looking back on working with traditional UV arc at Grafiche Antiga, Michielin said: “In the past we have used highly reactive UV drying systems… this gave us problems with production times, having to wait for bulbs to start up and cool down.

“Also, when we had to wash the blankets we had to turn off the system for safety and then turn it back on; therefore the standby times were long, productivity was affected. Today with the UV LED system we don't have any machine downtime, the system turns off and back on instantly… it has greatly shortened our production times.”

The new UV LED system is backed up with full technical support from GEW and Fornietic, although Michielin has yet to put this support network to the test.

“GEW gave us complete satisfaction with regard to assistance, as the UV system is connected remotely; every day it is monitored and we receive a monthly productivity report,” he said.

“This is also very useful for scheduling maintenance of the system itself. GEW has rapid and local technical support through Fornietic, who will arrive within a few hours to fix any problem… but so far this has never happened.”

Michielin sums up his view on the new working relationship with GEW: “When we started, we were looking not only for a supplier but also a partner, and GEW, for Grafiche Antiga, is a partner.”

Learn more about GEW’s LeoLED technology and how it can help your business here.

Alternatively, speak to the GEW sales team about LeoLED at drupa – Hall 16, booth E01.