Version 13 of Imp was officially launched this week, following a successful alpha and beta testing programme. The highly modular software suite can be configured for virtually any application and process.

According to the company, the software democratises the ability to automatically generate winning quotes that maximise profits by minimising waste.

The new features were largely driven by customer feedback.

“Technological and algorithmic innovations are important, but what is more important is listening to your customers and choosing the right problems to solve,” said InSoft Automation CTO Sashikanth Goparaju.

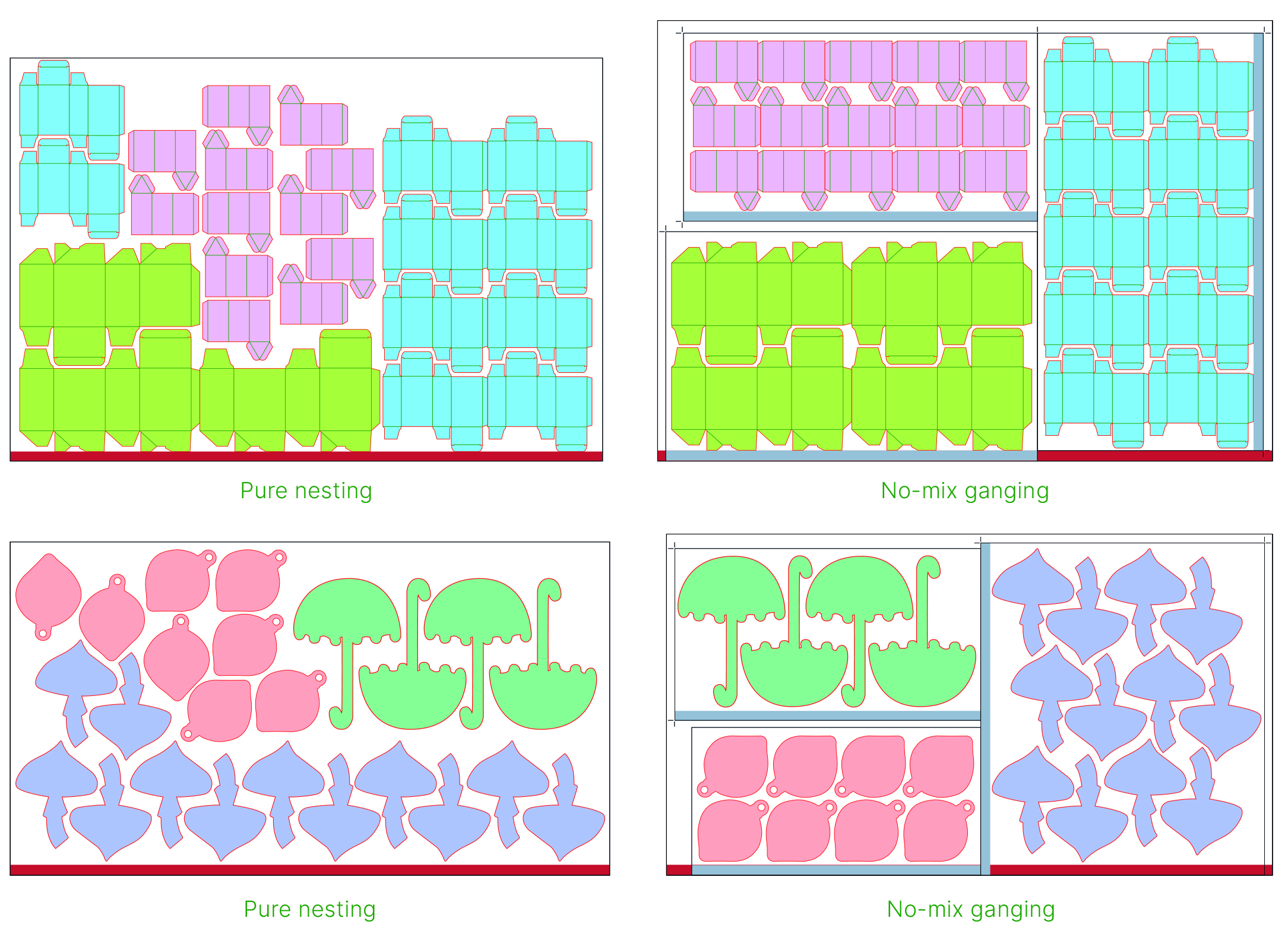

No-mix ganging allows each job to be isolated on the sheet, so it can be cut into smaller sheets and maintain job integrity through finishing workflows.

No mix ganging is a chargeable option on top of the die-cut nesting feature

No mix ganging is a chargeable option on top of the die-cut nesting feature

Joining no-mix ganging as a flagship feature update in Imp 13 is a wholesale revamp of the software’s label printing capabilities.

The significant enhancement to label printing functionality was in response to the increasing trend of short-run labels produced via digital workflows.

Additional controls have been added to boost the ensure correct label orientation, fewer overruns, uniform gaps between labels, no-splitting of single labels into multiple lanes, and limiting the number of lanes to match the configuration of slitter knives.

In terms of multi-discipline developments, hands-free estimation has also been built into version 13. This enables the new software to generate a plan, estimate and quotes/job-cards/routing XML automatically from ImpFlow.

Other new v13 features include refined algorithms for symmetrical interlocking patterns, the latest Adobe PDF Library 18.0.4 to maximise compatibility, enhanced support for embellishment separation exports through the dashboard, and several other functionality improvements to the user interface.

And while the previous iteration had been able to produce QR codes, the latest version also adds Datamatrix codes, which can be read from any angle.

As well as a whole host of technical developments to simplify operation, the pricing model has been similarly reconfigured, meaning users under an annual maintenance contract get free access to updates, upgrades, and support. With only optional new features like no-mix ganging coming at an additional cost.

“The beauty of our software is that it adds value to mom-and-pop shop and 1,500 employee companies. We have standalone module and a comprehensive Application Programming Interface [API or SDK] for integration with MIS/ERP solutions,” said Santosh Mulay, vice president, business development.

At its core Imp consists of two main modules, one for imposition and ganging and one for estimation. The imposition module typically takes the job ticket from the MIS/ERP which it then feeds to the estimation module to automatically generate the quote.

The highly modular software can be configured for virtually any application and is used by around 500 companies worldwide, covering more than 1,000 licenses. Users’ production technologies span sheetfed and roll-to-roll digital, production inkjets, flatbed and reel-to-reel wide-format, textile printers, sheetfed litho, web offset, flexo, and gravure.

“The methodology adopted for estimation enables a non-technical person to create accurate quotes consistently,” said Mulay.

“It is about generating order winning quotes with built-in software intelligence.”