The Swiss manufacturer and Heidelberg subsidiary revealed the MatteJet concept at Labelexpo Americas last September.

CEO Dario Urbinati told Printweek: “Inkjet has some really great features but one of the problems with inkjet is it’s always a bit glossy, and this was a hindering factor in further inkjet introduction in specific segments.

“So we said let’s look into the possibility to do a surface modification in a way that the ink becomes matte.”

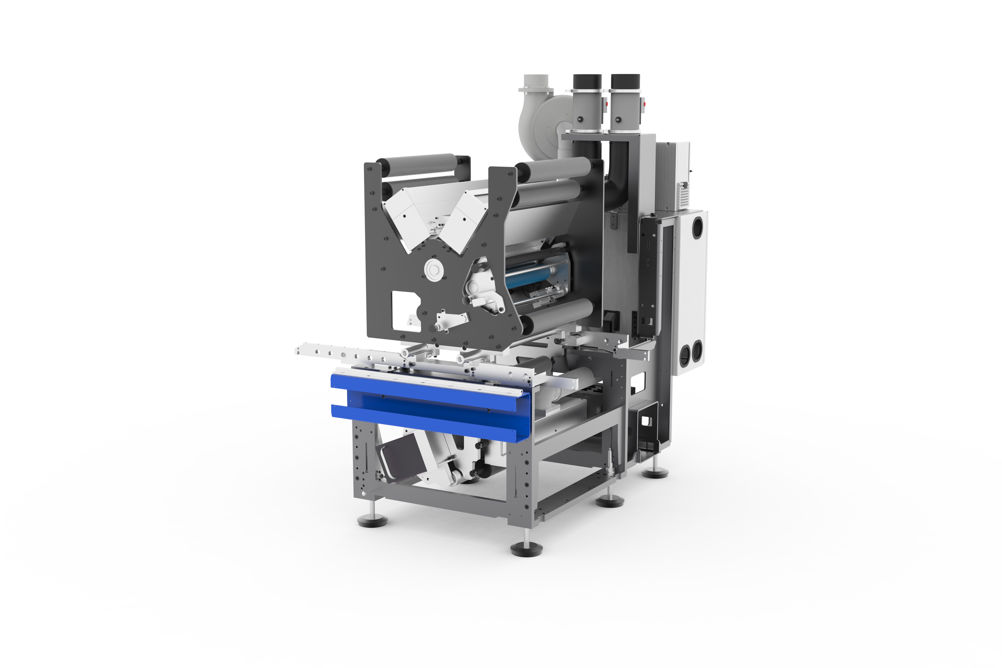

MatteJet was developed at the Gallus Experience Center innovation hub in St Gallen, Switzerland. It means label printers do not need to use additional coatings or post-printing processes to achieve the desired effect.

Urbinati said the surface modification involved a special lamp, but would not divulge further details.

UK-based curing and drying specialist and long-standing Gallus partner GEW played a key role in the development.

Gallus said the modular device – which can be retrofitted to the Gallus One digital press – opened up markets for inkjet printing such as high-end wines and spirits.

The group said the global wine label market was estimated at more than $3.5bn (£2.7bn), and projected to hit $5.8bn by 2033.

Urbinati said the MatteJet demonstrated its commitment to “closing the gap between the vast promise of digital technologies and the current reality for businesses across our industry”.

“Three years ago, with the launch of the Gallus One, we addressed the TCO barrier to profitable digital labels. With MatteJet, we’ve taken this concept further, bringing all the advantages of digitally printed matte labels to premium brands – including short runs, reduced inventory, enhanced sustainability, personalization, and on-demand printing,” he stated.

Pricing was not disclosed.