“You need to brave to invest in the current climate, we had the option to delay, but we’re a bold business and when we bought it a couple of years ago we took the view that it’s a start-up with £4m of customers already,” said managing director Ian Smith.

“We’ve managed to put the business on revenue streams of just under £6m last year and we believe the right investment in the right technology in the right markets is going to put us in a good position, whatever happens.”

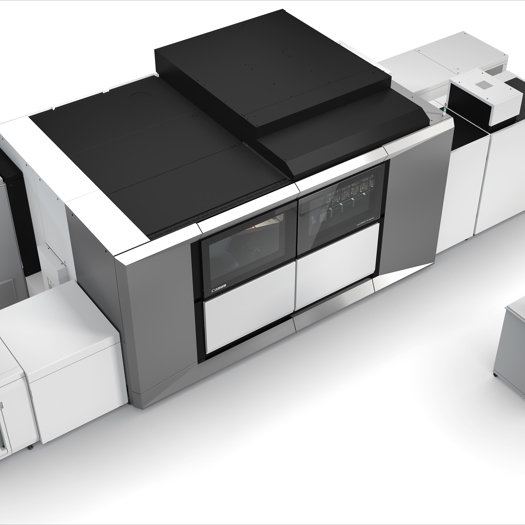

The firm’s new 210 A4 images per minute (ipm) Canon VarioPrint iX-2100, which was unveiled in April, is additional capacity that will join a Canon digital inkjet battery that includes a sheetfed VarioPrint i300 and a continuous feed ColorStream 3900 high-speed inkjet, installed last year.

“We diversified the business quite a lot since we bought it [in October 2018]. The i300 was towards the beginning of that journey and we onboarded around 50 publishing customers from scratch in 18 months, purely short-run academic and trade type books, picture books, children’s books – quite a broad range of publishing customers,” said Smith.

“They were mostly won over by the quality of the i300, which, depending on the substrate, is a really good match for litho and we got a lot of business transitioned from short-run litho and a little bit from toner, so we got work from both ends.”

According to Smith the i300 is currently running 24-5 and is soon likely to be at full capacity even after the firm reinstates the weekend shift.

“It’s the busiest machine in the factory, even during the slightly suppressed volumes of late.”

The Gloucester business had hoped to install the new iX-2100 in the next few weeks, but due to some pre-installation work being required on the power at its Ashville Road factory installation has been pushed back to late August for late September production.

“We need to keep growing, we’re winning new customers all the time in that part of the business, so the new machine is for new volume,” said Smith.

He first saw the €750,000 machine demonstrated under NDA in Canon’s Venlo demo facilities in the Netherlands, and was immediately won over.

“We were really impressed. The resolution is obviously a step up on the i300, but the main thing is the broader range of substrates we’re going to be able to run. We’re using litho stocks on the i300 anyway, we don’t use optimised stocks, which is a great attribute. The iX just broadens that range out. So, we can do more business with existing customers and win more new business as well.”

The new iX-series can handle offset coated paper from 90-350gsm and uncoated 60-350gsm.

“One of our guys here has been trained over in Poing on how to produce a ‘recipe’ for a new substrate and has worked with their [Canon] technicians as well, so when we’ve chosen to challenge the machine with a new substrate, he’s able work with their technicians remotely to ‘tune the machine in’.”

Smith said the consistency, productivity and reliability of Canon technology had been a key factor in the decision-making process.

“With toner and liquid toner, they have this constant calibration going on, which means repeatable is sometimes not achievable in terms or print job to a reprint, which is important on book products, but when you’re putting droplets of ink in paper as you are with the i300 and iX, you tune the substrate into the machine, so that you have that repeatability without the constant need for calibration. So we find consistency is another major factor in their favour.”

While the firm opted for the slightly slower iX-2100, it is field upgradable to the 320 A4ipm (9,000 SRA3iph) iX-3200 specs.

Severn already runs the fastest i300, capable of 300 A4 ipm, and with the new iX it will increase sheetfed capacity by around 75%-80% with no increase in labour costs as the machines will be side-by-side and run by the same operators.

“But I think somewhere down the track we will do a field upgrade,” said Smith.

As well as the soon to be expanded bank of Canon digital engines, Severn also operates two B2 Komori H-UV litho presses, and a raft of inhouse finishing services including stitching, PUR, and hard and soft book binding.

It also runs Enfocus Switch workflow automation to link in with customer systems. With even closer automation and integration with customer systems one of the key drivers of the appointment of former CPI Books chief technology officer Mark Allington as technical director.

“The idea is to create an environment where we’re very easy to work with,” said Smith.

The firm’s diversified work mix consists commercial, publishing, direct and transactional mail, which according to Smith has afforded it strong protection from the business impact of Covid-19.

It remained in production throughout lockdown, with around 25% of its 55 staff furloughed and a run rate of above 50% through May, 65% in June, and is on target to achieve around 75% of "normal" revenues in July. Around 15% of its staff are still on furlough.

“I’m not going to say it [Covid] hasn’t caused a few problems managing our costs and revenues, but I expect that because of our diversification and investment strategy that we’ve had less to worry about than a lot of people," said Smith.

“We expect to be back to pre-Covid levels by the end of August,” he added.

After which point, and after the iX-2100 is bedded in, Smith said the single site firm hadn’t ruled out looking at future M&A activity to fuel it's next growth phase.