The Bury St Edmunds-based label printer commissioned the MPS in September and has also this year taken on a second Xeikon CX3 digital label press and an AB Graphic Digicon 3 finishing line in January, and will install an SRI Re-reeler and rotary screen unit for an existing Arsoma flexo machine before the year is out.

The company would not disclose the cost of the investment.

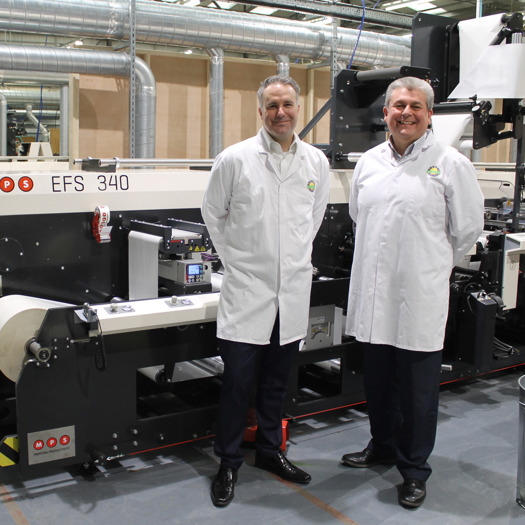

Chairman Tom Allum said that the MPS, Abbey’s second, is twice as productive as the eight-colour Gallus UV flexo press that it has replaced, and is intended to continue the trend of £5.6m-turnover Abbey’s three consecutive years of double-digit sales growth.

Its MPS EF-340 is the first in Europe to be configured with a GEW ArcLED UV system. Abbey’s first MPS will now take on the majority of its peel-and-reveal label work, with the new machine taking a wider variety of jobs.

“This will fulfil the demand for the next year to 18 months without further investment in flexo,” said Allum.

“The label industry is quite buoyant, especially after LabelExpo it is on a real high. The interesting thing with the industry is that those who put in digital presses have also gone on to put conventional presses in a year or two later.

“It was a frustration of mine coming from a litho background that flexo presses didn’t really move on. There was narrow-web UV flexo but since the late 90s and early 2000s they haven’t really moved on, but now they have really upped their game.

Running at 200m/min and with a web width of 340mm, the machine has been installed with APC automation extension package, which contains servo positioning motors to automatically set the desired print pressure settings, the same configuration as Abbey’s first MPS press.

The GEW system allows the machine to switch from conventional UV curing to LED curing. While the LED system’s lamps are more expensive than UV, they last up to 20 times longer and the system uses up to 50% less power, with Allum adding that a switch to LED had not happened yet but was imminent.

He said: “Conventionally if I want to change over from a UV to an LED system I would have to replace all the lamps and spend money to change over. With this system it gives me the option of literally unscrewing it and telling the machine it’s going to be an LED bulb. If I want to go LED in the next few months, I can change over very quickly with minimal investment.

“It’s nearly as simple as changing a lightbulb.”

37-staff Abbey has now called time on its investment programme but will be looking to expand its 2,100sqm premises in summer 2018, having already added 90sqm last year. It has upped staff by 10 and sales by £2m in the past three years.