The 10-colour new generation Rapida 105, which will arrive in October, is only the second in the UK. The press will be fitted with KBA's "no sidelay" technology, which was unveiled at last year's Drupa.

According to KBA, grippers on the feed drum can cause the sheet to move in the press. The system allows the sheets to be correctly positioned without sidelays, allowing for faster running speeds.

"We have found some distortion in the first five units of a long perfector but not in the second five," said Printhaus operations manager Tim Houghton. "We believe that without sidelays there is less trauma in the sheet and less stress to pull the sheet over."

The 10-colour press will join an existing six-colour KBA Rapida 105 at the Northampton firm.

"We wanted to push forward to the next stage," said Printhaus joint managing director Mark Hughes. "Investing in this equipment was the only way we could get more capacity."

The spend is part of a shift in strategy for the firm, which has traditionally used Heidelberg. It currently has a 10-colour Speedmaster 102, which will move from the firm early next year.

Hughes added: "We have recently achieved ISO14001 and the KBA presses are more environmentally friendly. We are looking at reducing alcohol levels to zero or near zero."

Printhaus has also won a contract to print 64pp A4 magazine The Environmentalist for the Institute of Environmental Management & Assessment.

Have your say in the Printweek Poll

Related stories

Latest comments

"And here's me thinking they bought the Docklands Light Railway."

"15 x members? Why don't they throw their lot in with the Strategic Mailing Partnership (SMP) and get a louder voice?"

"Some forty plus years ago I was at a "sales" training seminar and got chatting to the trainer after the session had finished.

In that conversation he told me about another seminar he had..."

Up next...

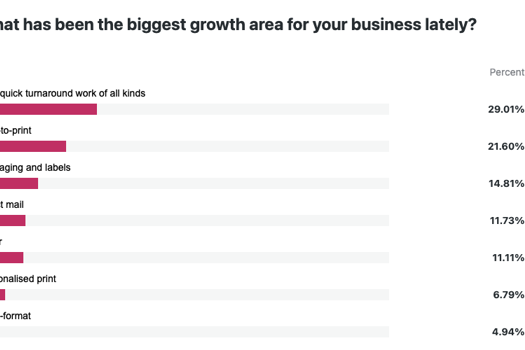

29% say quick turnaround work best growth area

Printers see opportunity in quick turnarounds and web-to-print

Commitment to developing talent recognised

Apprenticeship award for Coveris

2024 saw a sharp rise in response rates

JICMail data reveals growth in customer acquisition through mail campaigns

Scottish group has international ambitions